Nothing Seals or Protects Better than Spray Foam!

read more

read more

Spray Foam Adds Strength to Building Structure.

read more

read more

Polyurethane Foam Strengthens Your Home or Building.

-

-

The walls in your home are the main structural component of the building. In wood frame

construction, the weight of the roof, shingles, standing rain water and any snow add weight and

exert downward forces on the walls resulting in a compressive force.

Strong winds and gusts from storms also impose lateral forces onto your home's walls. These

forces can distort the walls with what is called a "shearing force."

Building codes require that your home's walls be designed to withstand these various forces and

loads. However, when walls are built to just the minimum standards, while still safe, symptoms of

movement such as creaking and shaking during high winds or occupant usage often occurs.

Higher density, closed cell spray foam insulation inside your stud walls fully adheres to both the

exterior sheathing and the studs, reinforcing both. With this added rigidity, there will be less wall

movement due to wind, vibration, and occupant activity. Additionally your walls have greater than

code required resistance to "racking events" such as hurricanes or other strong wind situations.

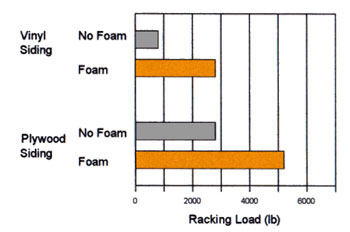

SPF also can add structural strength to buildings. NAHB Research demonstrated SPF filled walls

could add from 75% to 200% racking strength to walls of OSB, plywood, light gauge metal, vinyl

siding or gypsum board.

Racking Test

Shearing forces on a wall tend to distort the wall from its original shape as a rectangle into a

parallelogram. To test a wall's resistance to the shear forces imposed by wind loading, engineers use

a "racking test." An 8 ft. x 8 ft. model wall is built and placed in a large frame. The base of the wall is

secured to the frame and a horizontal (lateral) force is applied at one upper corner. The force is

increased in 400 lb. increments until the wall structure fails.

Spray Foam's affect on wall strength

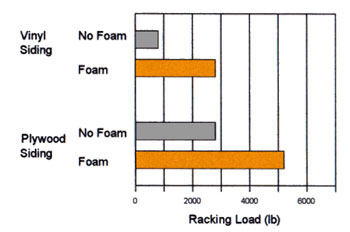

In a series of racking tests1, walls with and without spray-applied polyurethane foam insulation were

compared. Two exterior facing materials were tested:

1.Vinyl siding over 15-lb. building paper; and

2.Textured plywood siding.

All wall panels were faced with ½-inch sheetrock on the interior side and used 16 inch stud spacing.

For the stud wall panels that were insulated with spray-applied polyurethane foam, the stud cavities

were essentially completely filled with foam of 1.5 lb/ft³ density.

As the graph indicates, stud walls filled with spray-applied polyurethane foam add significant strength

to home walls. Furthermore, for each load applied, the foam filled walls deformed less and offered

greater resilience.

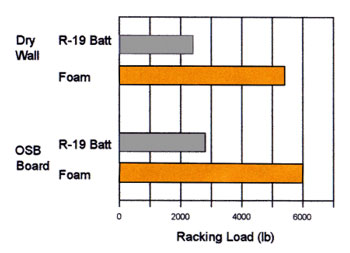

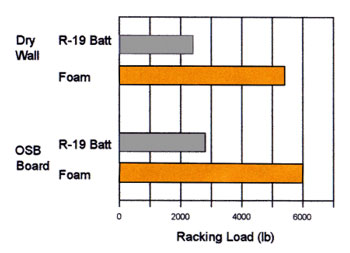

In a second series of racking tests2, spray-applied polyurethane foam insulation was compared with

conventional R-19 glass fiber batts. In one comparison, the wall panels were faced both sides with

dry wall. In the other comparison, the wall panels were faced one side with OSB (oriented strand

board) with dry wall on the opposite side. In both cases, the wall panels used steel studs spaced 24

inches on center and the average foam density was 2.26 lb/ft3.

Once again, the graph indicates the greater strength of the spray foam insulated wall system.

In a second series of racking tests2, spray-applied polyurethane foam insulation was compared with

conventional R-19 glass fiber batts. In one comparison, the wall panels were faced both sides with

dry wall. In the other comparison, the wall panels were faced one side with OSB (oriented strand

board) with dry wall on the opposite side. In both cases, the wall panels used steel studs spaced 24

inches on center and the average foam density was 2.26 lb/ft3.

Once again, the graph indicates the greater strength of the spray foam insulated wall system.

-